Call us: 9:00am - 6:00pm

+91-22-68520000

E-mail us

kushal@kushalmetal.net

Introduction

D-2 is a cold work steel that provide maximum wear resistance, great durability, exceptional front line maintenance and treating resistance. It is extensively used in threading rolls and dies, icy trimming, cutting, stamping tools & More.

Steel Properties : 12% ledeburitic chromium steel. Maximum wear resistance, good toughness. Best cutting-edge endurance and resistance to tempering, can be nitrided after special heat treatment.

Applications : Thread rolling rolls and thread rolling dies, cold extrusion tools, cutting and stamping tools for sheet thicknesses up to 6mm, precision cutting tools up to 12 mm. Cold pilger mandrels, circular-shear blades, deep-drawing tools, pressure pads and highly resistant plastic moulds.

E.S.R. materials, high compression strength and fine robustness. The spheroical annealed make it easily processed by shearing and cutting with no crake while processing.

Applied in thickness no less than 2mm punch mould, all kind of small mould for shearing and cutter together with screw rolled or slappered mould as well as some other forming mould like rulers.

Chemical Composition : (%)

| C | Si | Mn | Cr |

| 1.50-1.60 | 0.10-0.40 | 0.15-0.45 | 11.00-12.00 |

| Mo | W | V | P | S |

| 0.70-0.90 | - | 0.90-1.10 | ≤0.030 | ≤0.030 |

Grades Equivalent :

STANDARD |

BRAZIL |

AUSTRIA |

SWEDEN |

1.2379 |

VD2 |

K110 |

XW-41 |

EN |

SLOVANIA |

ITALY |

JIS |

X155CrVMo12-1 |

OCR12VM |

DUYO S2379 |

SKD11 |

S.KOREA |

CZECH REP. |

CHINA |

AMERICA |

STD11 |

2002K |

Cr12Mo1V1 |

D-2 |

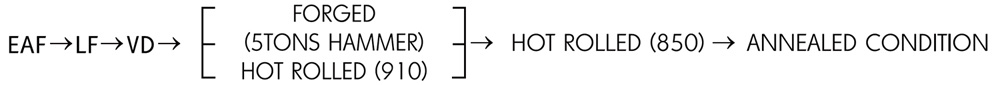

Production Process :

Round Bar :

Flat Bar :

| UT Standard : | Reduction Ratio : | Delivery Status : |

| SEP 1921, (DEC.84)E/e | As 1:4 or 1:5 | As Hot rolled & forged, delivery condition : Annealed |

Sizes of Round Bars :

Cold Drawn/Centreless Ground Bar |

Hot Rolled & Annealed Peeled |

Forged Annealed Turned |

Φ 2.0 - 14.4mm |

Φ 14.5 - 80.0mm |

Φ 81.0 - 1000mm |

Sizes of Flat Bars :

Thickness |

Width |

5mm - 150mm |

5mm - 810mm |

Sizes of Sheets :

Thickness |

Width |

Length |

0.5mm - 12mm |

810mm |

2500mm |

1) Heat Treatment Condition :

Quenching temperature : 1000-1040℃

Cooling Medium : Oil-cooling or air-cooling

Tempering temperature : 180-200℃, by two times;

Tempering Hardness : 63.0HRC

2) Heat Treatment Condition :

Quenching temperature : 1060-1080℃

Cooling Medium : Oil-cooling or air-cooling

Tempering temperature : 500-540℃, by two times;

Tempering Hardness : 59.0 - 61.0HRC

Get in Touch

Please Feel Free to Contact Us

Call us on

+91-22-68520000

Email us

kushal@kushalmetal.net