Call us: 9:00am - 6:00pm

+91-22-68520000

E-mail us

kushal@kushalmetal.net

Introduction

D-3 is a 12 % ledeburitic chromium tool steel with great wears resistance. It is used in cutting tools, trimming dies, blanking dies for paper and plastics & more. Partnering with a reputable D3 steel supplier ensures access to high-quality materials that meet the demands of various industrial processes, making it essential for manufacturers to choose a trusted source.

Steel Properties : Ledeburitic-high-carbon high-chromium tool steel, very high wear-resistance. A reliable D3 steel supplier can provide detailed specifications and guidance on selecting the right grade for specific applications.

Applications : Tools for cutting sheets up to 4mm thickness, trimming dies, blanking dies for paper and plastics, long- and round-section shear blades for sheet thicknesses up to 2 mm, drawing and deep drawing tools. Woodworking tools, stone pressing tools, pressure pads and highly wear-resistant plastic moulds, profile rolls.

Chemical Composition : (%)

| C | Si | Mn | Cr |

| 1.90-2.20 | 0.10-0.40 | 0.15-0.45 | 11.00-12.00 |

| Mo | W | V | P | S |

| -- | - | 0.20-0.20 | ≤0.030 | ≤0.030 |

Grades Equivalent :

STANDARD |

BRAZIL |

AUSTRIA |

SWEDEN |

1.2080 |

-- |

K100 |

-- |

EN |

SLOVANIA |

ITALY |

JIS |

X210Cr12 |

OCR12VM |

-- |

SKD1 |

S.KOREA |

CZECH REP. |

CHINA |

AMERICA |

-- |

2002 |

Cr12 |

D-3 |

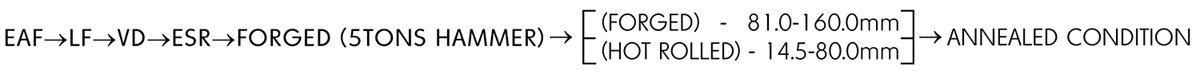

Production Process :

Round Bar :

Flat Bar :

| UT Standard : | Reduction Ratio : | Delivery Status : |

| SEP 1921, (DEC.84)E/e | As 1:4 or 1:5 | in annealed condition. |

Sizes of Round Bars :

Cold Drawn/Centreless Ground Bar |

Hot Rolled & Annealed Peeled |

Forged Annealed Turned |

Φ 2.0 - 14.4mm |

Φ 14.5 - 80.0mm |

Φ 81.0 - 610.0mm |

Sizes of Flat Bars :

Thickness |

Width |

5mm - 150mm |

5mm - 810mm |

Sizes of Sheets :

Thickness |

Width |

Length |

0.5mm - 12mm |

810mm |

2500mm |

Heat Treatments :

Soft annealing °C |

Cooling |

Hardness HB |

800 - 840 |

Furnace |

max. 250 |

Hardening form °C |

in |

Hardness after quenching HRC |

930-960

950-980 |

oil, hot bath 500-500 °C

air (up to 30 mm thickness) |

64 |

Tempering°C |

100°C |

200°C |

300°C |

HRC |

63 |

62 |

59 |

400°C |

500°C |

550°C |

600°C |

57 |

54 |

54 |

36 |

Get in Touch

Please Feel Free to Contact Us

Call us on

+91-22-68520000

Email us

kushal@kushalmetal.net