Call us: 9:00am - 6:00pm

+91-22-68520000

E-mail us

kushal@kushalmetal.net

Introduction

NAK-80 is a pre-Hardened, high performance, high precision, mold steel. Applications include plastic molds, rubber molds, jigs & fixtures, and press dies.

Smelting method : EAF+LF+VD+ESR

Main Characteristics : High monitoring performance even hardness, excellent discharging processing performance and texture processing performance. Molds can be used upon processing and no heat treatment is required.

Major Applications : Mirror plastic molds: Transparent plastic molds: optical instrument parts, compact disks, medical devices etc.

Molds underlining discharging processing surface quality.

Chemical Composition : (%)

| C | Si | Mn | Cu |

| 0.15 | ≤ 0.45 | 1.55 | 1.0 |

| Mo | Ni | Ai | P | S |

| 0.3 | 0.22 | 0.3 | ≤ 0.03 | ≤ 0.015 |

Physical Property : (%)

| Room temperature density (kg/m³) | Specific heat of room temperature (J/Kg.K) | 200°C thermal conductivity (W/m.K) |

| 7.8 | 460 | 22 |

| Elastic mouldsus (N/nm²) | Linear Expensivity (x10-6K) 20 ~ 200°C

20 ~ 400°C

|

| 218,000 |

12.3

13.2

|

Ultrasonic flaw detection :

Flaw detection standard: as per GB/T 6402-2008 Class 4 flaw detection standard or as per customer requirements.

Purity :

| Class A | Class B | ||

| Fine | Coarse | Fine | Coarse |

| 0.5 | 0.5 | 1.0 | 1.0 |

| Class C | Class D | ||

| Fine | Coarse | Fine | Coarse |

| 1.0 | 1.0 | 1.5 | 1.0 |

Delivery State :

(1) Delivery under pre-hardening state, delivery hardness 38~42HRC.

Supply Specifications :

| Flat Steel | Module |

| 16~120mm x 200~810mm | 120~400mm x 300~800mm |

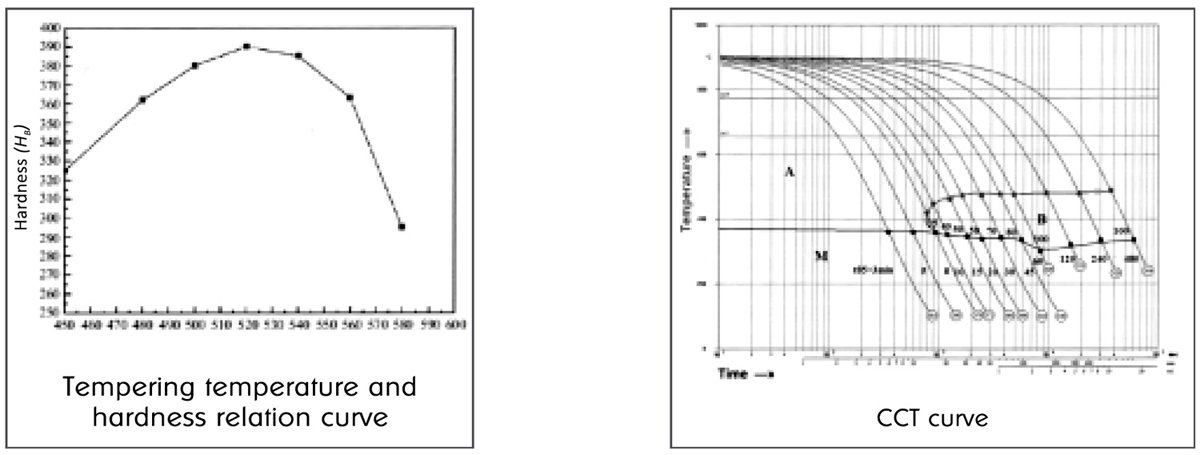

Heat Treatments :

| Softening annealing | Quenching | Tempering |

| Heating to 760°C for heat insulation and cooling to 600°C at 40°C/h | Delivery under pre-hardening state, no heat treatment, temperature of nitridation treatment 520°C | |

Get in Touch

Please Feel Free to Contact Us

Call us on

+91-22-68520000

Email us

kushal@kushalmetal.net